Air Flares

Air Assisted Flares offer an effective alternative to steam-assisted smokeless flares. Air flares meet needs where a waste stream will smoke if burned in an unassisted pipe flare and a steam assisted flare design is not feasible. This is common in process plants where steam production is limited or in cold climates where freezing condensate is a concern.

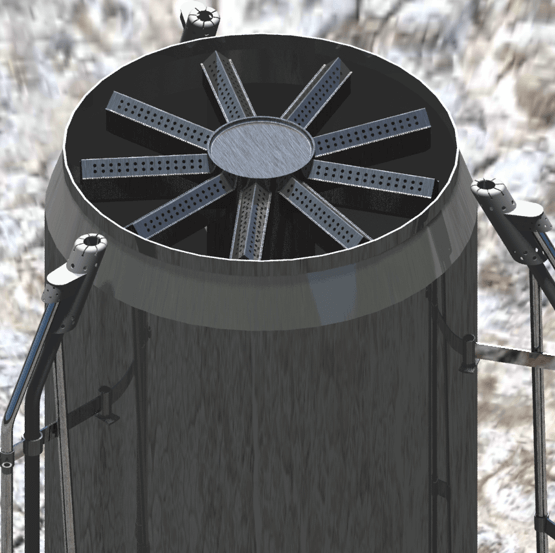

Air assisted flares use a blower to push combustion air up the stack into the combustion zone. The waste gas travels inside a riser that runs coaxially inside the stack carrying the air. Getting more air into the combustion zone increases the amount of hydrocarbon that the flare system can burn without smoke. Air assisted flare tips come in a variety of configurations and offer advantages such as:

- Low maintenance and long service life

- Low operating costs

- No steam or steam lines

- High smokeless capacity

- Low noise design available

- Online maintenance of smoke suppression equipment

- Extremely stable pilots

There are many options to consider when designing an air assisted flare system. Working with a knowledgeable flare designer is critical for safe and efficient operation. EnviroPro is knowledgeable and experienced in air flare applications. Contact us to discuss your project.