Steam Flares

Steam is used in steam assisted flare tips to either achieve smokeless operation, maximize tip life, and/or to shape the flame depending on the flare tip technology applied.

The amount of steam supplied to the flare must be precise. Excessive steam flow will decrease the destruction efficiency and could possibly extinguish the flame. Insufficient steam during a flaring event can cause the flare to smoke or wear prematurely.

Many refineries, and chemical plants, have called to discuss how the refinery sector rules would impact their business as it relates to flaring, especially in net heating value (NHV) calculation and pilot monitoring.

There are many considerations in designing a steam flare system. EnviroPro is knowledgeable and experienced in steam flare applications. Contact us to discuss your project.

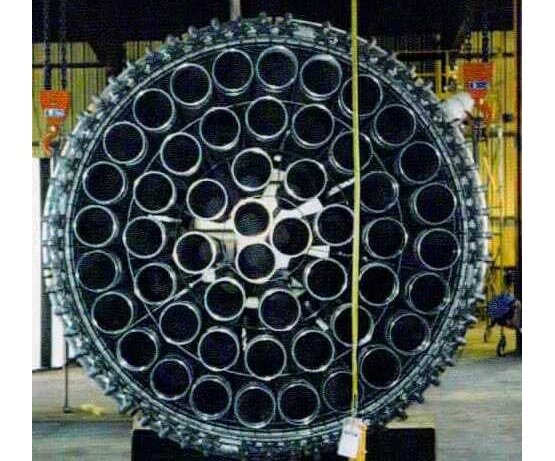

- IS3 Steam Flare Tip

- Upper Steam

IS3 Steam Flare Tip

This approach significantly reduces the amount of steam required to inject the same amount of air using upper steam tips. Relocating the manifold to a lower position on the flare tip allows a muffler to be installed, significantly reducing steam noise.

The IS3 is a great choice for many applications especially where customers seek maximized smokeless capacity and reduced noise, some of the most common include:

- Ethylene Plant Flare

- Coker Plant Flare

- Refinery Flare

- Butadiene Plant Flare

- Propylene Plant Flare

- Polyethylene/Polypropylene Plant Flare

Upper Steam

Upper Steam Assist flares incorporate a high-stability pilot and a flame retention system. With a high efficiency, low noise steam injection ring, the flare tip provides smokeless burning with quieter operation than traditional steam injection systems.