Ground Flares

Ground flare systems are often chosen due to their efficiency in handling multiple operating cases with large variations in flow rates, 100% smokeless capabilities, the ability to completely conceal flames, and operating noise is much lower than elevated flares. A low- pressure first stage may be assisted with steam or air for smokeless, but the second stage and beyond would not need assist air or steam since the pressure of the waste gas exiting the burner tips induces efficient air to flare smokelessly.

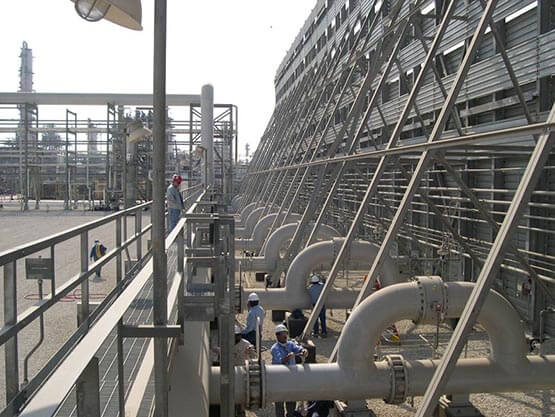

Ground flares can be “totally enclosed” or “multi-point”. Both of these technologies use a fence to conceal flames and protect surrounding areas from radiation and noise. All of the ground flare equipment, including pilots and pilot thermocouples, are located at grade. Thermocouples can be retractable for convenient and safe maintenance.

There are many considerations in designing a ground flare system. EnviroPro is knowledgeable and experienced in ground flare applications. Contact us to discuss your project.

- Multipoint Ground Flares

- Totally Enclosed Ground Flares

Multipoint Ground Flares

The flare field is surrounded by a fence that hides much of the flame from view and protects the surrounding area from radiation. All staging valves and controls are located outside the fence and are accessible for maintenance even when the flare is online.

Typical applications where multipoint ground flares are used include:

- Ethylene plants

- Poly ethylene and propylene plants

- Methanol plants

Multipoint ground flares are used wherever the flare gas flow is relatively high, 100% smokeless operation is required, higher DRE is desired and noise and light pollution must be kept to a minimum.

Totally Enclosed Ground Flares

Under certain circumstances, low pressure vapors can be flared smokelessly in a totally enclosed ground flare without the use of assist air or steam. Talk to the EnviroPro flare experts to see if your application fits.

Totally enclosed ground flares have also been used to flare vapors that are considered the process cases or day-to-day flaring of a plant with the emergency release of vapors piped to an elevated or multipoint ground flare.