Regenerative Thermal Oxidizers

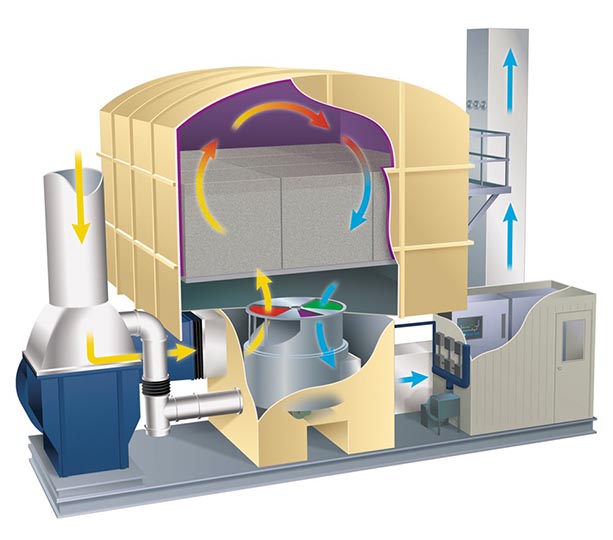

A regenerative thermal oxidizer, also called an RTO is defined by NFPA 86 as “a combustion device where the burner(s) can directly heat the VOCs or hydrocarbons after the gas stream is preheated to the destruction temperature by the periodic flow reversal of the gas stream through heat storage media that alternately have been heated by the product gases during an exhaust cycle and then have given up their heat to the incoming reactant gases during an inlet cycle.” RTOs are often used in applications to destroy high volume low heating value waste gases. Typical applications include:

- API Separator Vents

- Biomass Dryer Vents

- Equipment Off Gas

There are different approaches to Regenerative Thermal Oxidizer (RTO) design. These systems are designed to operate with a low VOC concentration while remining fuel efficient to prevent needing to combust the total air volume in the waste stream.

Contact EnviroPro to discuss your oxidizer applications!